About Us

Home

–

About

BOMBAY FASHION

– Crafting Quality Since 1987

Established in 1987, Bombay Fashions is a trusted name in garment manufacturing, known for our commitment to quality, craftsmanship, and client satisfaction. With over three decades of experience, we specialize in delivering end-to-end garment production solutions for brands, retailers, and designers across the globe.

From custom designing and sampling to bulk stitching and finishing, we offer flexible, scalable manufacturing services that adapt to your brand’s needs. Whether you're launching a new line or scaling an existing one, we ensure optimum Minimum Order Quantities (MOQs), competitive pricing, and on-time delivery—without compromising on quality.

Our Core Services

- Garment Manufacturing & Stitching

High-quality production across categories—menswear, womenswear, kidswear, and more. - Custom Designing & Sampling

In-house design assistance, prototyping, and pattern development. - Flexible MOQs

Ideal for both emerging labels and established brands. - Competitive Pricing

Cost-effective solutions with consistent quality control. - Quality & Timely Delivery

Streamlined operations ensure every order meets your expectations, every time.

At Bombay Fashions, we combine decades of expertise with a forward-thinking approach to help bring your designs to life—efficiently, beautifully, and reliably. Let’s build something great together.

Our Fabric Manufacturing Process

From Fiber to Fabric – Precision at Every Step

Certainly! Here's a rewritten, streamlined and professional version of the fabric manufacturing process section, specifically tailored to workwear fabrics such as poly-cotton, poly-viscose, and other blends:

Engineered for Durability. Designed for Performance. At Bombay Fashions, we specialize in producing high-performance workwear fabrics that meet the demands of durability, comfort, and functionality. Our fabric development process focuses on blends such as poly-cotton, poly-viscose, and other performance-enhancing synthetics—designed to stand up to rigorous use across industries.

1. Fiber & Yarn Selection

We start with carefully selected fibers to ensure long-lasting wear and superior strength. Our core fabric types include:

- Poly-Cotton (PC) – Breathable, durable, easy-care

- Poly-Viscose (PV) – Soft feel with excellent drape and resilience

- Poly Blends – Custom-engineered to suit specific workwear needs (e.g. stretch, flame-retardant, anti-static)

Yarns are spun with controlled twist and tenacity to ensure high tensile strength and fabric consistency.

2. Weaving & Fabric Construction

Using automated power looms, we produce a wide range of woven structures ideal for workwear applications, including:

- Twill weaves for added strength and abrasion resistance

- Plain weaves for lightweight, uniform finishes

- Blended stretch fabrics for mobility and comfort

We can customize GSM, weave pattern, and blends based on your requirements.

3. Dyeing & Color Fastness

We offer vat, reactive, and disperse dyeing techniques based on the fiber composition. Our dyeing process ensures:

- High color fastness to light, rubbing, and washing

- Shade matching across large batches

- Azo-free, REACH-compliant dyes upon request

We also accommodate corporate and uniform-specific color matching.

4. Functional Finishing

To enhance fabric performance, we apply a range of technical finishes including:

- Anti-pilling treatment

- Moisture-wicking / Quick-dry finish

- Shrink resistance

- Wrinkle resistance

- Softeners for wearer comfort

- Optional: Flame-retardant, Anti-bacterial, Anti-static finishes

Each finish is tested for durability and compliance with workplace standards.

5. Quality Control & Testing

All fabrics undergo rigorous QC checks including:

- GSM and shade verification

- Tear and tensile strength tests

- Dimensional stability (shrinkage control)

- Abrasion and pilling resistance

We ensure every roll is consistent, defect-free, and ready for garment production.

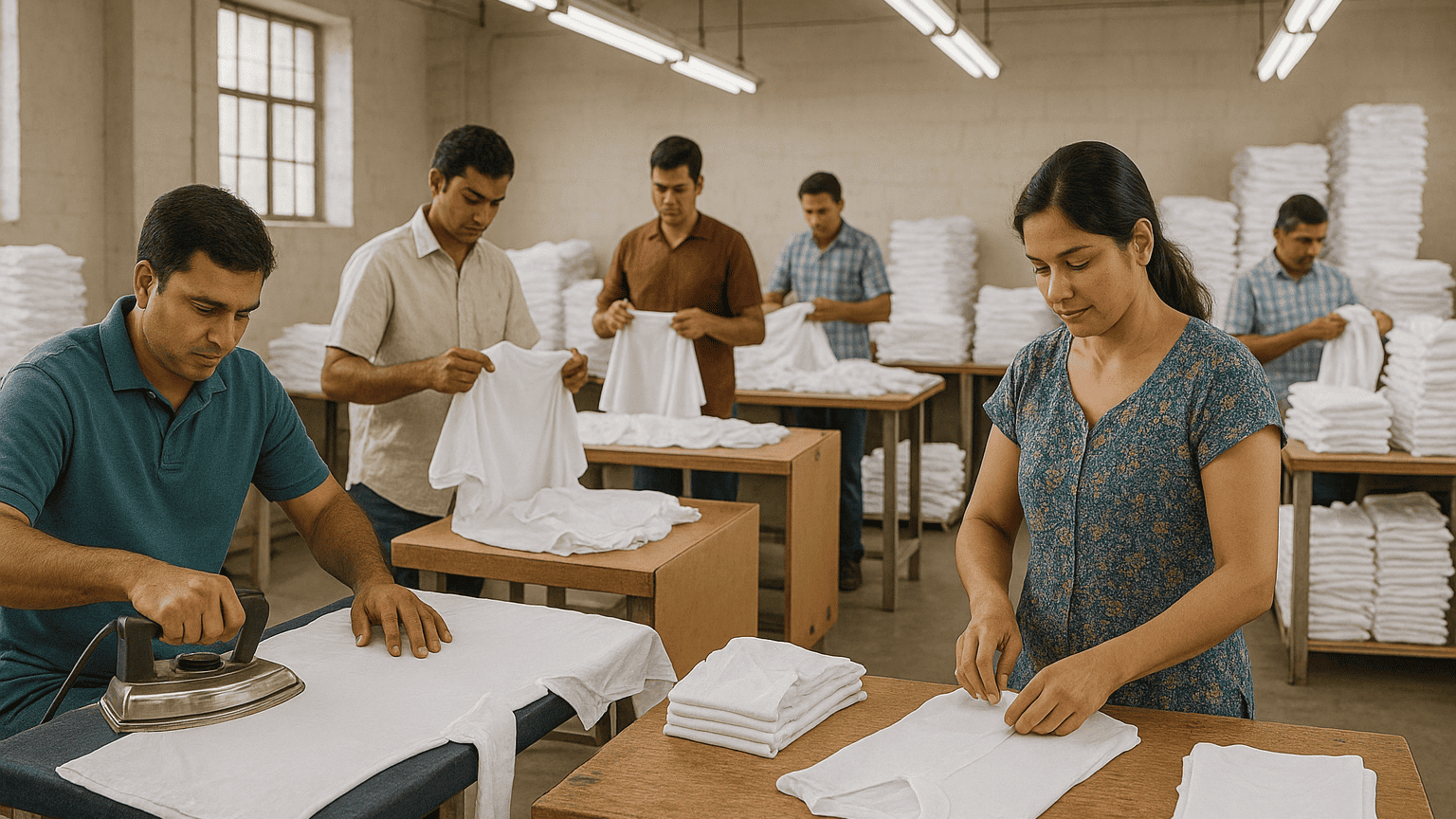

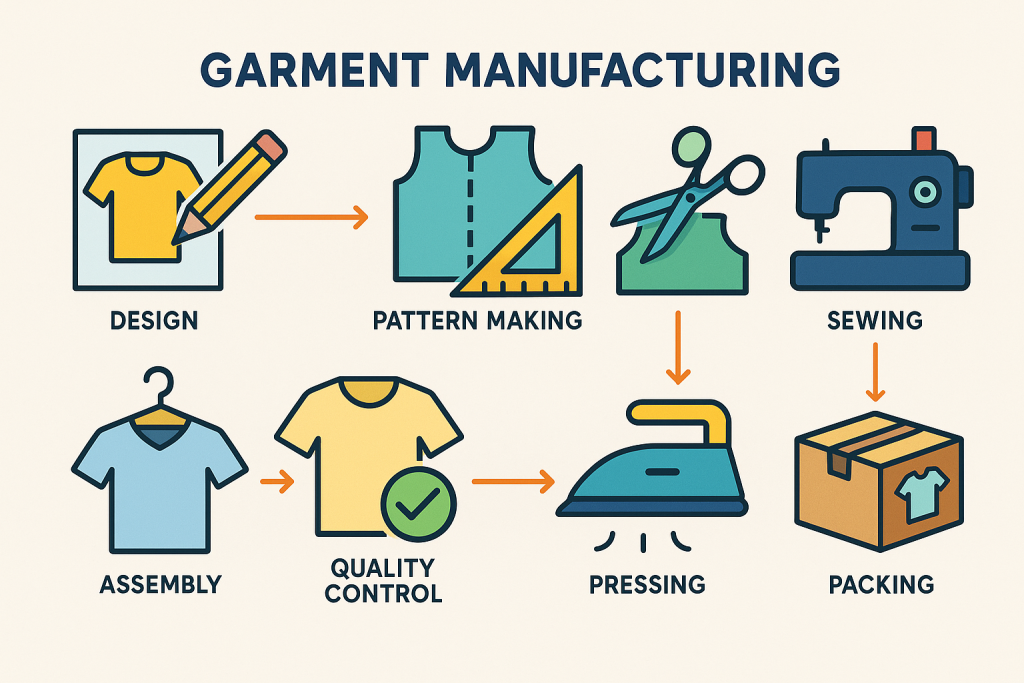

Our Garment Production Process

From Fabric to Finish – Precision in Every Stitch

At Bombay Fashions, we offer comprehensive garment manufacturing services, transforming high-performance fabrics into finished garments with precision, efficiency, and attention to detail. With decades of experience, we specialize in workwear, uniforms, and custom apparel, delivering both small-batch and large-scale production at industry-leading standards.

1. Tech Pack & Design Development

We work closely with clients to translate their vision into production-ready styles. Whether you provide a detailed tech pack or just a concept, our team can assist with:

- Pattern Making & Grading

- Sampling & Prototyping

- Customization of fits, trims, and finishes

- Size Set Development

Our in-house designers and technicians ensure that each garment is optimized for function, comfort, and visual appeal.

2. Fabric Sourcing & Cutting

With vertical integration from our fabric manufacturing, we use in-house or partner-supplied poly-cotton, poly-viscose, and blended fabrics. Once approved, fabrics go through:

- Precision marker planning for fabric efficiency

- Automated or manual cutting based on order volume

- Layered cutting for bulk production consistency

3. Stitching & Assembly

Our skilled workforce and modern machinery handle a wide range of sewing requirements, including:

- Lockstitch, Overlock, Flatlock, and Coverstitch

- Reinforced seams for industrial-grade durability

- Custom construction techniques for utility garments

- Uniform and standardized production workflows

We accommodate custom garment types including shirts, trousers, coveralls, jackets, and corporate uniforms.

4. Trims, Embellishments & Branding

We offer full control over garment detailing, including:

- Buttons, zippers, Velcro, and snap fasteners

- Reflective tapes, functional pockets, utility loops

- Heat transfers, embroidery, woven labels, and custom branding

- Compliance with workwear safety standards

All trims are quality checked for durability and colorfastness.

5. Finishing & Packing

Each piece is professionally:

- Pressed/ironed

- Checked for stitching, specs, and final QC

- Tagged, barcoded, and packed as per client requirements

We offer bulk packing, individual polybagging, and custom packaging solutions.

6. Delivery & Logistics

We manage domestic and international shipments with:

- On-time dispatch and lead time tracking

- Flexible logistics (FOB / CIF / door delivery)

- Documentation support for exports

Come visit us

Work Space

We are available for you to come down and personally meet us. Have a look at the variety of products we develop.

Shop 17, 18,Talam Arcade,

KG Circle Majestic 560009

43,Hennur cross road,

HBR Layout 4th Block, Bangalore 560043